Valve actuators are the backbone of countless systems—controlling the flow of fluids, gases, and even controlling critical processes in oil and gas, power, chemical, etc. When they work, no one notices. But when they don’t? The consequences can range from poor performance to downright dangerous.

The problem? Many engineers and operators don’t even realize their actuators are failing—until it’s too late.

The Hidden Costs of Bad Actuators

When a valve actuator starts to go bad, it doesn't always announce itself with flashing lights and alarms. Instead, you might see subtle changes: a little lag in response time, a slight drop in efficiency, or intermittent valve behavior that’s easy to overlook.

Ignore those signs, and the real trouble begins:

Production Delays: A valve that won’t open or close properly can throw an entire process line into instability.

Safety Hazards: In oil and gas, chemical and power applications actuator failure can lead to dangerous material leaks or critical system malfunctions.

Reduced Efficiency: A valve that’s constantly fighting against a faulty actuator is one that isn’t operating at peak performance.

Common Symptoms of Failing Actuators

Even if you’re not looking for actuator problems, your system might be showing you signs:

Valve Chattering: That rattling noise? Could be an actuator struggling with bearing alignment or stem leakage.

Internal Leaks: If your valve is leaking beyond spec, the actuator may have low balance pressure or force.

External Leaks: Tubing leaks are red flags for both actuator failure and safety concerns.

Stiction: If the valve sticks and requires extra force to move, the actuator may be fighting a losing battle.

You Don’t Know What You Don’t Know—Until You Use the Profiler

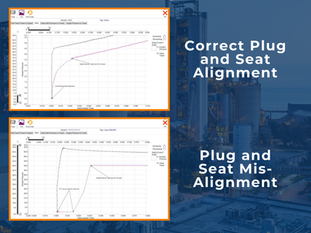

Here’s where SofTek Engineering’s Profiler system comes in. Most engineers don’t have time to second-guess their valves or actuators. The Profiler takes the guesswork out of diagnostics.

By analyzing valve performance in real time, the Profiler can detect early signs of actuator failure—before it becomes a safety issue, before it causes a shutdown, and before it eats up your budget.

With the Profiler, you’ll know:

If your actuator is sized correctly

If internal or external leaks are exceeding tolerances

If the valve is chattering, sticking, or lack of force

And most importantly, if the actuator needs repair or replacement

The Bottom Line

A bad actuator might not scream for attention—but the damage it can cause is loud and clear. Whether you're managing a plant or fine-tuning high-performance valves, staying ahead of actuator issues is crucial.

The Profiler from SofTek Engineering is your early warning system. It doesn’t just test valves—it protects your process, your people, and your bottom line.