In the world of industrial maintenance and diagnostics, Motor motor-operated valves (MOVs) play a crucial role, in managing flow, pressure, and other vital factors across various applications. SofTek Engineering's Profiler System has long been the gold standard for valve diagnostics, and with its latest expansion into MOV testing, it’s set to revolutionize how professionals manage and optimize these critical components. Whether your operation involves pneumatic or hydraulic actuators, the Profiler’s cutting-edge tools allow for a deeper, data-driven approach to diagnosing and maintaining linear and rotary MOVs.

Key Advantages of the Profiler System for MOV Testing

1. Advanced Position and Stroke Diagnostics

The Profiler System's precise position sensors deliver real-time insights into actuator positioning. For rotary valves, it measures degrees of rotation; for linear valves, it measures stroke length in inches or millimeters. This ensures every valve position is perfectly aligned with your operational needs. Additionally, the system includes limit switch verification, which confirms that each valve's open and closed states are correctly set and visible to the control room, supporting smooth, optimized flow control.

2. Comprehensive Motor and Actuator Analysis

MOV motor health is paramount, and the Profiler System delivers on this front by tracking RPM, motor responsiveness, temperature, and torque. Monitoring phase currents across single and three-phase motors enables early detection of wear or failure potential. By ensuring all motor phases operate smoothly, operators can avoid costly downtime and meet strict operational standards with confidence.

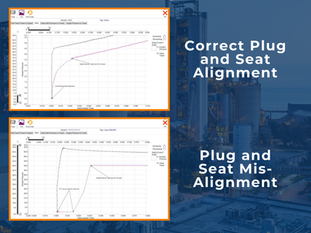

3. Detailed Friction and Seating Analysis

The Profiler System also tackles traditional valve friction and seating analysis with precision. Utilizing current readings instead of load measurements, it produces a comprehensive friction curve that outlines breakout and running currents, providing insights into each valve’s unique friction profile. For linear valves, the system captures detailed seating compression and torque requirements, helping to ensure optimal sealing and prevent leakage.

4. Modulating and ON/OFF Testing Capabilities

The Profiler System’s testing versatility extends to modulating and ON/OFF MOVs. It can execute modulating tests using a 4-20 mA signal, measuring key metrics like motor RPM, stroke time, and response speed. Additionally, it performs full-stroke operations for ON/OFF valves with either 24V DC or 120V AC signals, recording stroke time and speed to validate compliance with design specifications.

5. Enhanced Maintenance and Wear Diagnostics

Predictive maintenance is one of the most powerful tools for extending equipment life and preventing failures. The Profiler System enables this by identifying “slop” or dead bands within gears, performing seat leak tests, and using laser-based bubble counting to verify tight shutoff. These diagnostics enable operators to detect issues early, proactively address wear, and ensure each MOV operates smoothly and leak-free.

Why SofTek’s MOV Testing Solution Is the Smart Choice

SofTek’s Profiler System is designed to empower operators and technicians with precise, actionable data, making MOV maintenance smarter and more efficient than ever. It supports the entire range of valve types, from upstream to downstream, in both rotary and linear configurations. Technicians trained on the Profiler System gain a robust toolkit, allowing them to conduct thorough predictive maintenance, reduce costly breakdowns, and extend valve life. This suite of features provides an unprecedented level of control and insight into MOV performance, making it essential for any operation aiming to enhance reliability and efficiency.

Take your valve diagnostics to the next level with SofTek Engineering’s Profiler System.