Air leaks might seem like a minor nuisance in pneumatic systems— but over time, they can lead to major losses in compressed air, increased energy consumption, and ultimately, higher operating costs. From worn components and loose fittings to vibration and environmental wear, the sources of air leaks are numerous. Left unchecked, even the smallest leak can compromise system efficiency, drive up expenses, and result in unexpected downtime.

What Causes Air Leaks?

Air leaks can stem from a variety of common issues, including:

Loose Fittings and Connections: Over time, couplings, hoses, seals, and fittings/tubing can loosen, especially in high-vibration environments.

Improper Installation: Incorrect installation of filters, regulators, and compression fittings can create slow but persistent leaks.

Corrosion: Moisture and environmental conditions can degrade pipes and fittings, creating gaps for air to escape.

Vibration: Reciprocating compressors and other moving equipment can gradually loosen connections and hardware.

Open or Loose Drain Cocks: Dirt or rust buildup can jam drain traps open, continuously bleeding compressed air.

Contamination: Debris, dirt, and salt deposits on valve seals can interfere with their ability to maintain an airtight seal.

Detecting Leaks: Where Profiler Comes In

Traditionally, air leaks are detected using a variety of methods: listening for hissing sounds or applying soap solutions. While effective, these methods are often time-consuming, subjective, or limited.

Profiler takes air leak detection to the next level.

With Profiler’s real-time diagnostic analysis, you can:

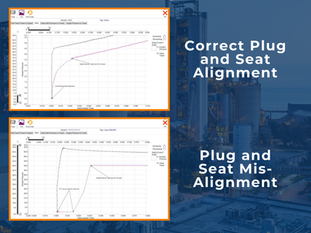

Pinpoint leaks instantly using actuator analysis and valve performance graphs.

Catch minor leaks early before they grow into major issues, thanks to the system’s high sensitivity to changes in pressure and movement.

Verify repairs immediately by comparing “as found” vs. “as left” results side by side.

Profiler doesn’t just detect air leaks—it helps you understand why they’re happening and what to do about them.

Fixing Leaks with Confidence

Once a leak is identified, corrective action becomes clear and straightforward:

Tighten loose fittings and connections.

Replace worn o-rings, tubing, or filter/regulators.

Repair or replace compromised tubing.

And with Profiler, every step of that process can be monitored, measured, and validated in real time—saving your team time, money, and headaches.

Final Thoughts

Air leaks are an invisible drain on your system’s efficiency and your bottom line. Profiler brings visibility, precision, and insight to your leak detection strategy—empowering you to fix the problem fast and keep your pneumatic valves/actuators/positioners running at peak performance.

Ready to eliminate guesswork and take control of your valves?

Let Profiler help you STOP the leak—literally. JUST TEST IT!