Enhance Your Valve Diagnostics with SofTek's Profiler System

SofTek Engineering’s Profiler System now provides specialized testing capabilities for Motor Operated Valves (MOVs), enabling comprehensive diagnostics and performance analysis across both linear and rotary valves. This expansion brings pneumatic and hydraulic actuator testing standards to MOVs, ensuring your valve systems achieve peak performance and maintain their intended functionality over time.

Key Features & Capabilities:

Advanced Position and Stroke Diagnostics

-

Real-Time Positioning: Gain precise insights into actuator position with enhanced position sensors, allowing for detailed measurement in degrees of rotation for rotary valves and inches/millimeters of stroke length for linear valves.

-

Limit Switch Verification: Ensure accurate valve positioning with limit switches that indicate open/close states directly to the control room. Our system verifies these are set correctly, maintaining the proper stroke length for optimized flow.

Comprehensive Motor and Actuator Analysis

-

RPM and Speed Tracking: Monitor motor RPMs to verify speed responsiveness and meet desired stroke timing. Track motor operation, ensuring MOVs meet strict operational standards.

-

Temperature and Torque Monitoring: Evaluate motor health by monitoring temperature and torque, especially in smart actuators equipped with torque sensors. This allows for a proactive approach to maintenance.

-

Phase Current Analysis: For both single and three-phase motors, our system reads phase currents, detecting discrepancies that could indicate motor wear or potential failure, ultimately ensuring all phases run smoothly.

Detailed Friction and Seating Analysis

-

Friction Curve Insights: Instead of traditional load or force measurements, we utilize current readings to assess friction, creating a friction curve that details breakout and running current for thorough analysis.

-

Precise Seating Profiles: Capture exact seating profiles, especially for linear valves, with data on the seating compression and torque requirements, helping identify optimal sealing conditions and preventing leakage.

Modulating and ON/OFF Capabilities

-

Signal Testing: Execute modulating tests with a 4-20 mA signal, including ramp and command signals, while capturing motor RPM, stroke time, and response speed. This data allows for a seamless evaluation of actuator responsiveness and precision.

-

ON/OFF Control: Our system provides the same robust diagnostic tools for ON/OFF MOVs, enabling full-stroke operations with either 24V DC or 120V AC signals. Stroke time and speed are recorded to ensure compliance with design parameters.

Enhanced Maintenance and Wear Diagnostics

-

Predictive Maintenance: Use phase current analysis and detailed resolution tests to detect dead bands, or “slop,” within gears and attachment points, allowing for early detection of wear.

-

Bubble Counting and Leak Testing: Perform seat leak tests with cutting-edge laser bubble counting for tight shutoff verification, ensuring leak-free operation for the long term.

Why Choose SofTek’s MOV Testing?

Our Profiler System's new MOV testing capabilities empower operators to perform high-precision diagnostics across all valve types, from upstream to downstream, in both rotary and linear applications. Technicians trained on the Profiler system can perform predictive maintenance, preemptively identifying issues to avoid costly downtime and extend valve life. By utilizing our suite of tests, from sensitive resolution steps to detailed seating compression analysis, users gain a comprehensive toolset that was previously unavailable in MOV diagnostics.

Elevate your valve maintenance and diagnostic protocols with SofTek Engineering’s Profiler System – the next step in reliable, data-driven valve management.

Analysis & Test Results

Hydro test accessory

Key Features:

-

High-Precision Sensors: Includes a 10k pressure sensor and Type-K thermocouple for accurate and reliable hydro testing.

-

Portable & Versatile: Can be integrated with existing hydro benches or used with blind flanges for on-site testing at customer locations.

-

Comprehensive Reporting: Generates detailed PDF test reports with graphs and data results, facilitating easy customer approval before shipment.

-

Expandable System: Capable of testing up to four valves simultaneously, with customizable testing times ranging from minutes to 24 hours.

-

Remote Monitoring: Integrated cameras and computer access allow tests to be witnessed remotely, reducing the need for costly on-site visits.

Seat leak accessory

The Seat Leak Accessory for the Profiler™ Diagnostic System offers a comprehensive solution for fully automated or manual seat leak testing in compliance with ANSI/FCI 70-2-2006 standards.

Key Features:

-

Precision Testing: Equipped with three mass flow meters (.5, 10, and 200 slpm) and a laser bubble counter, ensuring accurate and reliable leak detection.

-

Pressure Monitoring: Includes a high-performance pressure sensor (150 psi) to monitor system pressure during tests.

-

Advanced Stroke Speed Analysis: Features dead time(s) and TC2 (86.2% ISA) measurements, providing precise control over valve stroke speed.

-

Solenoid Control: AC/DC solenoids with current reading capabilities, enhancing control and monitoring during testing.

-

Limit Switch Setup: Comprehensive limit switch setup and testing capabilities.

-

Spring and Torque Measurement: Measure spring rate, set pressure, and torque (breakout, running, seating, and total) to ensure valve integrity.

-

User-Friendly Design: Intuitive interface and easy-to-use controls, ideal for production, field service, and end users.

-

Customizable: Fully configurable to meet specific customer needs and requests.

-

Traceability: Complies with NIST traceability standards, ensuring all measurements are accurate and verifiable.

Seat Leak Testing Components:

-

Seat Leak and USB Interface Box: Connect via yellow, gray, and white cables for laser bubble testing.

-

Limit Switch Cable and Software Setup: Supports up to two limit switches with easy cable setup.

Information & Analysis:

-

ANSI/FCI 70-2-2006 Compliance: Enter all required information in the user-friendly info screen.

-

Comprehensive Graphs and Analysis: Track and analyze valve position, actuator/supply pressures, solenoid current, springs, torque, and limit switches with detailed graphical representation.

-

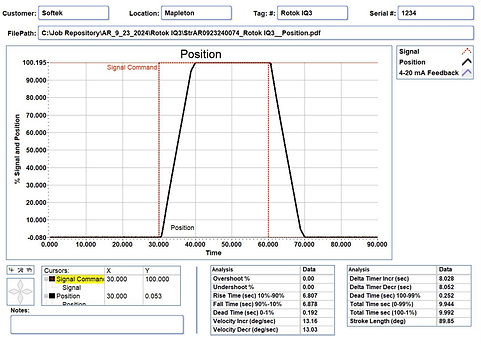

Position: Monitor command and valve position, including overshoot, undershoot, rise/fall times, dead times, velocity, total times, and stroke length.

-

Pressures: Analyze command, valve position, actuator, and supply pressures, including max supply pressure and pressure droop.

-

Torque: Assess command, valve position, actuator pressures, and various torque metrics (breakout, running, seating, total).

-

Solenoid Current: Evaluate command, valve position, and solenoid current (AC/DC), with calculated and actual current readings.

-

Springs: Examine actuator pressure versus valve position, spring rate, and spring set parameters.

-

Limit Switches: Configure and analyze limit switch settings, including enable/disable thresholds.

-

Complete block/isolation valve tests with detailed PDF printouts. Analyze seat leak, bubble counter, limit switch setup, and more with comprehensive graphs and reports.

Traceability: Ensures an unbroken chain of measurement comparisons to stated references, as defined by NIST.

Invest in Profiler MOV—Enhance your Valve Diagnostics with the Best in the Industry.